Description

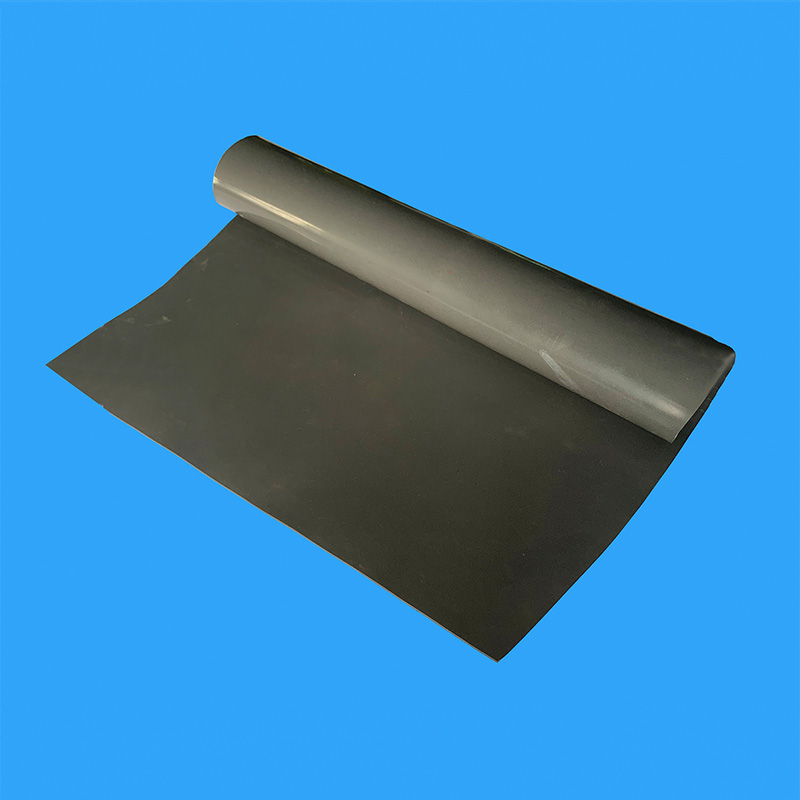

- Suitable for electrical products with strict fire retardant requirements, such as fire retardant gaskets, fire retardant sealing rings, wire sleeves, terminal covers and other products.

- Suitable for foaming silicone rubber products with strict fire retardant requirements.

| Physical Properties | Test Method | Unit | DATA | |||

| Model | NJ-352H Series | NJ-352N Series | NJ-352M Series | NJ-FF7261 | ||

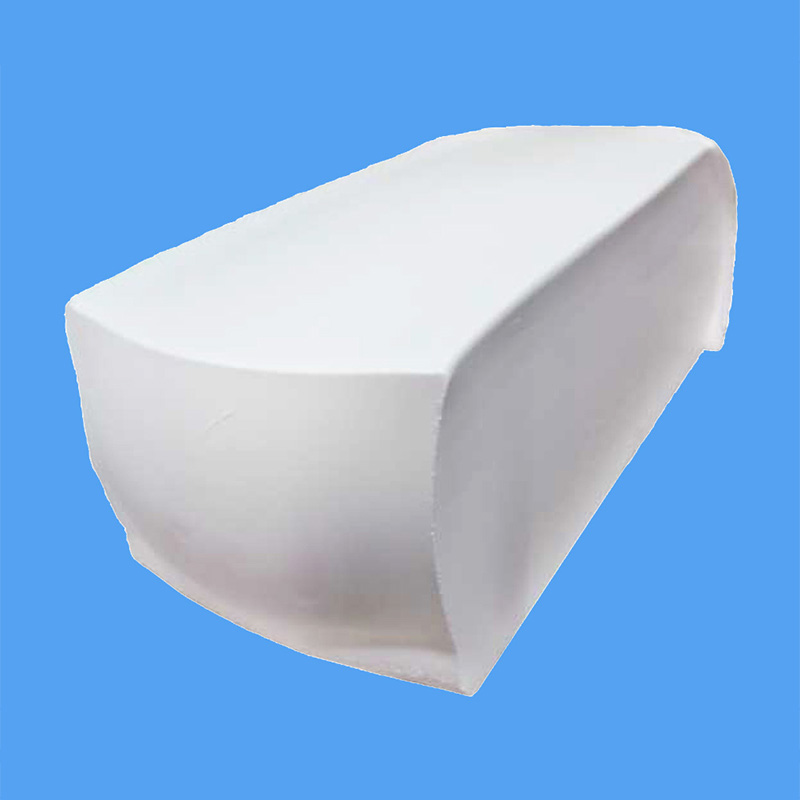

| Color | Visual Inspection | Black/White | Black/White | Black/White | White | |

| Shore Hardness | GB/T 531.1-2008 | A0 | 30-80 | 30-80 | 30-80 | 57±3 |

| Density | GB/T 533-2008 | g/cm3 | 1.44-1.50 | 1.44-1.50 | 1.44-1.50 | 1.29±0.02 |

| Tensile Strength | GB/T 528-2009 | Mpa | ≥4 | ≥4 | ≥4 | ≥3.8 |

| Elongation At Break | GB/T 528-2009 | % | ≥240 | ≥240 | ≥240 | ≥400 |

| Tear Strength | GB/T 529-2008 | KN/m | ≥12 | ≥12 | ≥12 | ≥13 |

| Flammability | UL-94 | Class | 1mm 94V-0 | 2mm 94V-0 | 3mm 94V-0 | 2mm 94V-0 |

| Sample Cured Condition | Curing agent and quantity: C-8A×1.2%;curing temperature/time: 170℃×6Min. | |||||

| Process Suggestion | Suitable for mould pressing, extrusion and calendering technology. 60A/70A/80A are better for extrusion. Pressing/injection molding technology: Add some release agent if product structure is complicated. Extrusion technology: Add some quantity frost prevention agent. | |||||

| Package | 20Kg/Carton. | |||||||||

| Storage Condition | Room temperature less than 25℃, do not contact water, avoid sun exposure. | |||||||||

| Expiry Date | 10 months, suggest to finish within 3 months. If expired, can continue to be used after remilling and qualified inspection. | |||||||||